Copper alloys

Overview

Copper and its alloys are not widely used because most have the following disadvantages —

- Relatively low quality factor Q (indicative of high loss)

- Low fatigue strength

- Low resistance to wear and cavitation

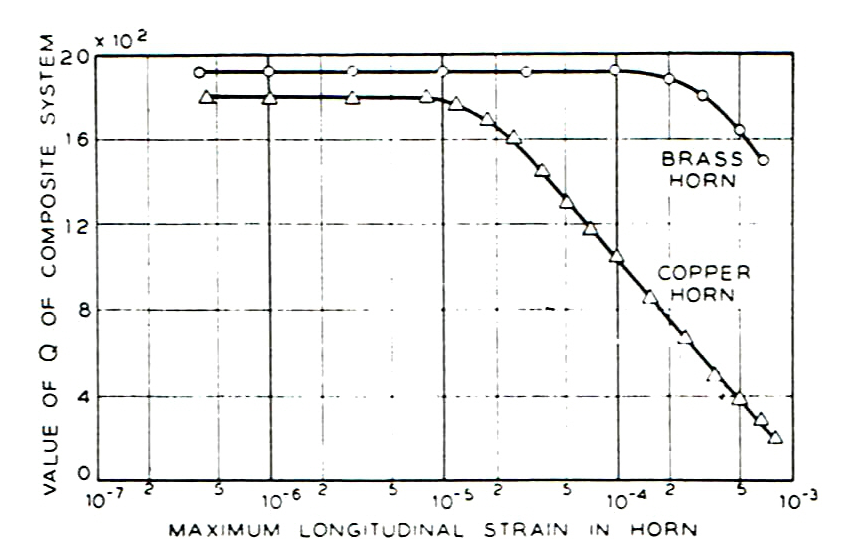

Mason's ultrasonic tests (figure 1) show that copper has a Q of approximately 1800 up to a strain of 1.0e-5 beyond which the Q decreases rapidly. The Q of brass is approximately 1900 up to a strain of 1.2e-4 beyond which the Q decreases rapidly. For comparison, Ti-6Al-4V has a Q of approximately 20000 for strains up to 3e-3.

|

|

|

Good thermal conductivity - back driver?

Bell brass