Cavitation erosion

Contents

- Overview

- Test methods

- Materials

- Replaceable tips

- Coatings

- Appendix A. Testing materials for cavitation erosion

- Appendix B. Parameters that correlate to cavitation erosion

- Appendix C. Cavitation erosion data for various materials

- Also see cavitation

- Figures

- Figure 1. Cavitation erosion of nickel 270

- Figure 2a. Liquid processing horn with tip

- Figure 2b. Replaceable tip

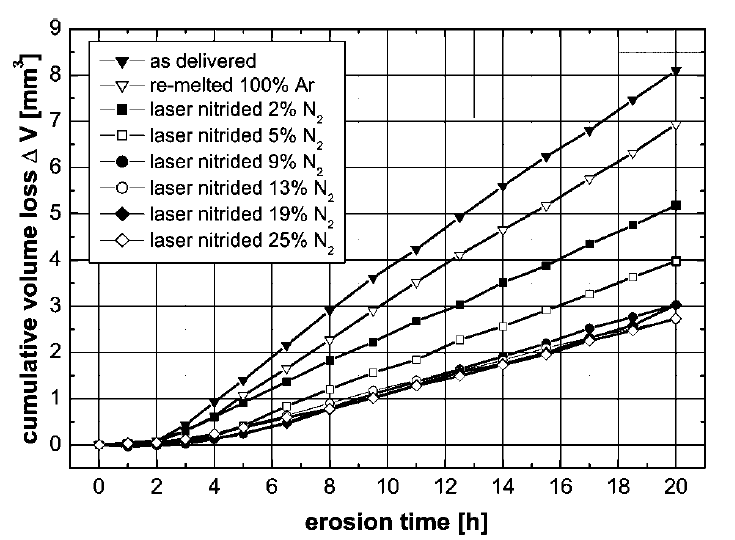

- Figure 3. Cavitation erosion of Ti-6Al-4V without and with titanium nitride coatings

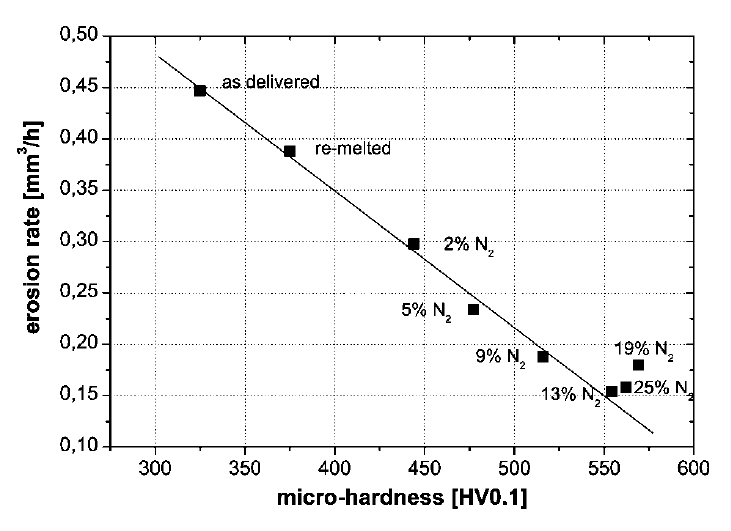

- Figure 4. Cavitation erosion rate of Ti-6Al-4V without and with titanium nitride coatings

- Figure A1. ASTM-G32 cavitation erosion test apparatus

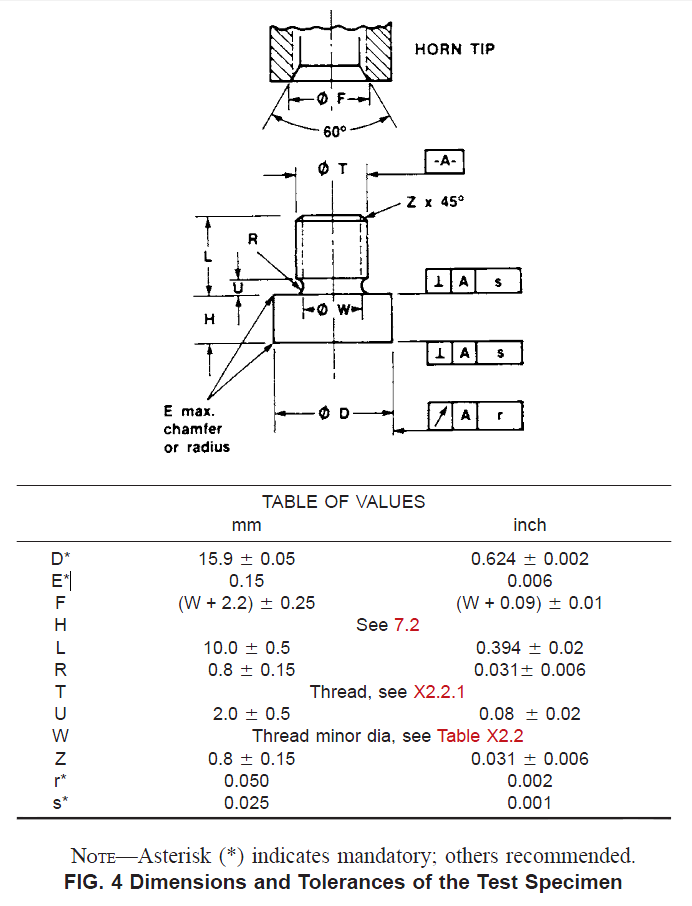

- Figure A3. ASTM-G32 test specimen tip dimensions

- Figure A4. Cavitation stages

- Figure A99. Cavitation erosion

- Figure B1. Effect of shot peening on surface hardness

of 321 stainless steel (SS) and pure iron (Fe) - Figure B2. Effect of grain size and hardness on resistance to cavitation (Re)

- Figure C1. Erosion rates for various metals

- Tables

- Table C1. Erosion rates for various materials

Overview

Cavitation erosion occurs when a material is exposed to a cavitating fluid. The collapsing cavitation bubbles cause intense shock waves and microjets which, in turn, cause highly localized surface stresses. Repetition of this loading due to repeated bubble collapses causes local surface fatigue failure and the subsequent detachment or flaking off of pieces of material. (Brennen, section 3.6, p. 91)

The figure below shows the typical progression of cavitation erosion (from Young, p. 15; 25 kHz, 44.5 microns, 24 °C water).

|

|

|

In ultrasonics the cavitation is often deliberately produced by an ultrasonic horn in order to see the effect on a process (e.g., ultrasonic homogenization). However, this cavitation gradually removes material from the face of the horn. This causes several problems.

- As the tip shortenes the frequency of the system increases until the power supply can no longer start the horn.

- As the horn face becomes pitted by erosion, it produces less cavitation which thereby impacts the process.

- The eroded material may contaminate the process.

These problems can be mitigated by a combination of four approaches — 1) using a horn material that has higher cavitation erosion resistance, 2) using a coating that has higher cavitation erosion resistance, 3) improving the surface finish, and 4) using a horn with a replaceable tip.

Attacks grain boundaries (weakest point) --> try single crystals (no grain boundaries).

Test methods

The test method for ultrasonic cavitation erosion is specified by ASTM cavitation erosion specification G32-10. Appendix A gives a brief overview.

Materials

Metals

Titanium is generally the default resonator material for applications involving cavitation. It has acceptable (but not exceptional) cavitation erosion resistance. However, it is relatively inert to many liquids. Stainless steel is also used. (See Appendix C for cavitation erosion data for various materials.)

Elastomers

Elastomers are not suitable as resonator materials. However, they may be useful to prevent transmission of ultrasonic energy or to reduce cavitation erosion (mainly of stationary surfaces). Knapp[1] (p. 370) indicates that these materials may show "no cavitation damage at all" under relatively low-intensity cavitation. Light[1] (p. 45) found that vulcanized Ethylene Propylene Diene Monomer (EPDM) sheet had about three times better erosion resistance than 316L stainless steel when exposed to 50 micron peak-to-peak vibration at 20 kHz. (Note: painted EPDM, which was nonvulcanized, performed poorly.)

Replaceable tips

A solid horn would be expensive to replace after cavitation erosion. Instead, expendable tips can be used with horns whose face diameter is less than about Ø25 mm (see figures 4). See tips.

|

||||||||||

|

|

Coatings

Various coatings have been used to improve cavitation erosion (compared to titanium as a reference). These coatings can be applied to tips but can also be used where the base horn material must be preserved (e.g., titanium), where the horn's face area is too small or too large to accept a replaceable tip, or where the face is irregular. Coatings can be classified according to their thicknesses: thin or thick. They can also be classified according to whether they are ductile or brittle.

Thin coatings

Coatings can be considered thin if the inertial forces due to the ultrasonic vibration are relatively low. Then the adhesion force does not have to be high. These coatings include chrome and titanium nitride.

Hard chrome

In his cleaning tank transducer patent, DeCastro[1] (column 2, line 25) asserts that 2 mil (0.05 mm) hard chrome reduces cavitation erosion by a factor of 10 compared to the 316L stainless steel base metal. DeCastro attributes this to the higher hardness of the chrome (60 Rc versus 25 Rc) although other factors may certainly be involved. (DeCastro does not specify the test procedure nor provide any supporting data. Also note that Bregliozzi found that cavitation erosion of stainless steel is highly dependent on the material's grain size.)

Titanium nitride

Because of its hardness and good adhesion, titanium nitride has long been used to reduce cavitation erosion. However, the process can't be applied arbitrarily. Kaspar[1] investigated laser deposited titanium nitride on Ti-6Al-4V for various percentages of nitrogen in a nitrogen-argon atmosphere. The cavitation tests were conducted according to ASTM G32-92 in deionized water at 25°C. Cavitation was induced by 20 kHz longitudinal oscillation at 40 microns peak-to-peak with a standoff distance of 0.50 mm between vibrating tip and the stationary sample. Figures 5 and 6 show the results. Note that increasing the nitrogen atmosphere up to about 13% (micro-hardness ~550) steadily reduces the cavitation erosion. At that level the erosion rate is about 3x lower than the as-delivered titanium. However, further increases in nitrogen and hardness don't further reduce the cavitation erosion.

|

|

|

|

|

|

Matsumura[1] has found that even when the titanium nitride has been removed, the base material still has improved erosion resistance due to the remaining residual stress.

Thick coatings

Due to their mass, thick coatings must resist substantial inertial forces. Then inadequate adhesion between the coating and the base material can be a problem. If such coatings are also brittle then they cannot be applied over a large area (e.g., cleaning tanks) because the ultrasonic flexure will cause them to crack.

Sapphire

Sonics & Materials[1] reports, "Results with affixation of sapphire and ceramic tips have also been poor. They are expensive and shatter or separate within minutes." A source with knowledge of this particular process reported —

- The sapphire was a single crystal.

- The sapphire was attached to the horn with an adhesive. The process was initially successful and give high erosion resistance. However, at some point the formulation of the adhesive apparently changed ...

- One problem was that the cavitation would attack the adhesive so the adhesive would fail rather than the sapphire.

- Sapphire could not be used with a replaceable tip because distortion (bending) of the tip during tightening caused the sapphire to fracture.

Note, however, that the erosion results with coatings may depend heavily on how they were applied or bonded.

Appendix A. Testing materials for cavitation erosion

Test methods

The test method for ultrasonic cavitation erosion is specified by ASTM cavitation erosion specification G32-10. Note: the number after the dash ("10" in this case) refers to the year of the last revision. However, previous versions are likely to be substantially similar.

In the standard method, a test specimen of the desired material is machined as a tip and screwed to an ultrasonic horn. If a coating is being evaluated then the coating is applied to the tip. The tip is activated in a liquid (typically water) and the rate of cavitation is determined.

An alternate (unofficial) method is often used. In this "stationary specimen method" the test specimen is attached to a stationary platform and the vibrating horn tip is placed in front of it. The cavitation from the horn then acts to erode the stationary specimen. Unfortunately, various findings show inconsistent results because the horn-specimen gap has not been standardized (ASTM G32-10, p. 17).

ASTM G32-10

The following is a brief overview of ASTM cavitation erosion specification G32-10. See that source for complete information.

The general test procedure is —

- Set up the test equipment as shown in figures A2. Note that the amplitude is specified as peak-to-peak.

- Machine the tips as shown in figure A3.

- Weigh the tip.

- Immerse the tip in the test liquid (often water, distilled or deionized) and run for a specified time.

- Remove the tip, dry the tip, and carefully weigh it.

- Repeat steps 4 and 5 until a termination criterion has been reached. For example, the test may be terminated when the average rate of erosion has reached a maximum and begins to diminish.

|

|

|

|

|

|

|

The test surface should be lightly machined, then ground and polished to a maximum surface roughness of 0.8 μm (32 μin.) in such a way as to minimize surface damage or alteration. The specimen is finished with 600 grit emery cloth, yielding a surface finish of 0.1 to 0.2 μm (4 to 8 μin.) rms. (pp. 5‑6)

Reporting the results

Figure A4 shows typical erosion stages in a cavitation test.

|

|

|

|

As figure A4 shows, cavitation rate of erosion is not constant with time so it cannot be fully characterized by a single number, nor can long-term behavior be predicted from a short-term test. ASTM G32-10 (p. 10) specifies that certain values must be reported.

- Maximum stable rate of erosion. This is the maximum linear (or near linear) erosion rate after the initial incubation period. This is the slope "B" of the "maximum rate line" of figure A4, typically expressed in μm/hour.

- Nominal incubation time. This is intercept of the maximum erosion rate line on the time axis (the value "A" of figure A4).

Some investigations may not confrom to ASTM G32-10 in which case other results may be reported. (These may be optional under ASTM G32-10.)

- Time to achieve a chosen mean depth of erosion (MDE).

- Mean depth of erosion (MDE) after a chosen exposure time. However, as ASTM G32-10 notes, "Because of the shape of the cumulative erosion-time curve, it is not meaningful to compare the mass loss or MDE for different materials after the same cumulative exposure time. (The reason is that a selected time may still be within the incubation or acceleration stage for a very resistant material, whereas for a weak material the same time may be within the maximum rate or deceleration stage.)"

- Terminal erosion rate. This is the slope "C" in figure A4 if the test has continued for a sufficiently long time.

Interpreting the results

When tests are performed according to ASTM G32-10 the results are reasonably repeatable for identical materials. However, materials that are nominally identical (in a macro sense) may actually may perform very differently when exposed to cavitation erosion. This may be due to processing differences, differing grain sizes, etc. Garcia[1] (p. 216) notes, "It is the experience of this laboratory that supposedly identical materials taken from different heats may have variations in applicable mechanical properties as great as 50%."

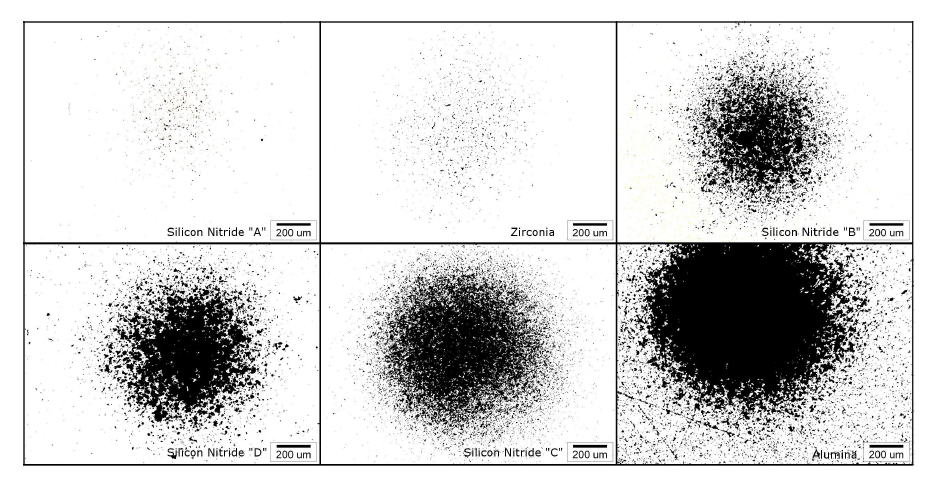

For example, figure A1 shows cavitation erosion of silicon nitride ("A", "B", "C" and "D") from different manufacturers after 120 hours, all tested under the same conditions (Fatjo[1], p. 12). For this test the material loss from silicon nitride "C" was 90 times greater than for silicon nitride "A".

|

|

|

In other investigations certain specifications of ASTM G32-10 may have been violated (e.g., using a different tip size, amplitude, frequency, etc.) or differing test termination criteria may have been used. Also, different cavitation liquids may be chosen where, for instance, the corrosive effects of sea water may accelerate the cavitation erosion. These problems mean that comparison of results among various investigators may be difficult.

Appendix B. Parameters that correlate to cavitation erosion

"Although there are some outstanding discrepancies, the tendencies are that cavitation resistance generally increases with increasing mechanical properties such as surface hardness, tensile strength, yield strength, ductility, strain energy to failure, etc., at least within groupings of relatively similar materials. However, large anomalies occur betweein different types of materials such as ductile metals versus strong brittle metals, metals versus ceramics, metals versus elastomerics, etc." (Knapp[1], p. 374)Hardness

Hardness is the primary material property that correlates with cavitation erosion resistance. Hardness in the base material can be produced globally (e.g., by through hardening) or locally (e.g., by surface hardening or shot peening).

Shot peening

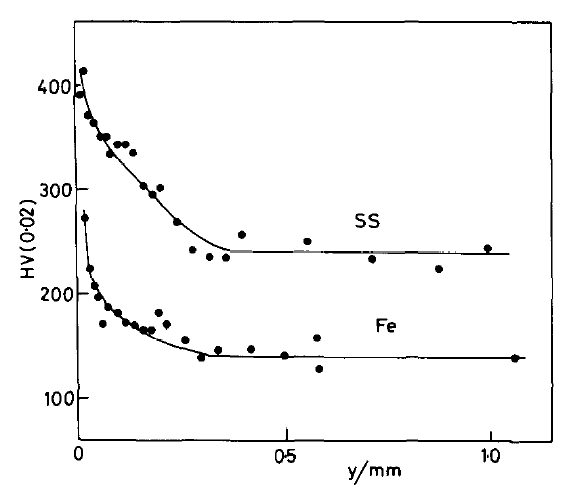

Tomlinson[1] conducted 20 kHz cavitation tests on shot peened 321 stainless steel (annealed) and pure iron in distilled water and 1% salt water. The shot peening work hardened the materials to a depth of 0.3 mm (figure B1). (Grade 321 stainless steel may have been chosen, in part, because it responds well to work hardening.) The specified amplitude was 15 μm (presumably peak-to-peak) and the water temperature was 50 °C. (In figure B1 "y" is the distance below the specimen's surface [mm]. The vertical axis is labeled as "HV 0.02". Although Tomlinson doesn't specify the meaning, it likely refers to the Vickers hardness scale with a load force of 0.1961 N. See Vickers Hardness Tester.)

|

|

|

Shot peening reduced the stabilized erosion rate by a factor of 5 in the distilled water and a factor of 13 in the salt water (Tomlinson's table 1, p. 238).

Surface finish

When a material is initially exposed to cavitation, there may be an initial stage during which the erosion rate is negligible compared to later stages. This incubation period can be extended if the surface is highly polished.

Grain size

Like fatigue, cavitation occurs on a microscopic scale. Thus, two materials that have nearly identical macroscopic properties (e.g., tensile strength) may have significantly different resistance to cavitation erosion. This is illustrated by Bregliozzi's research into the effect of grain size on 20 kHz cavitation of stainless steels. Figure 3 shows that the cavitation resistance Re in water increases with smaller grain size and hardness. (In the graphs, Re has units of hours per mean depth of erosion penetration (measured in micro-meters). pH is the measure of the acidity or basicity of the water; "pH 7" is neutral.)

|

|

|

Thus, it is not proper to say that material X is inferior to material Y unless the processing and microscopic characteristics of the materials are precisely specified. (Of course this doesn't apply to materials that are grossly different. For instance, any aluminum will be inferior to any steel for cavitation erosion.)

Appendix C. Cavitation erosion data for various materials

The following information is provided for reference. Many of the listed materials may not be suitable as ultrasonic horns because of loss, fatigue, cost, and/or material availability. For example, although many steels have lower erosion rates than titanium, their output amplitudes are limited by internal losses (heating). However, this heating problem can be improved with an optimized profile that reduces the local ultrasonic stress. In any case, some of the materials might still be suitable as replaceable tips or coatings.

Except as noted, the following data were obtained in accordance with ASTM G32-10 (see Appendix A); specifically —

- The cavitating fluid is room-temperature water.

- The amplitude is 50 microns peak-to-peak.

Knapp / Garcia

The following table is from Knapp[1] (p. 425) who adapted it from Garcia[1] (table 13, p. 130; table 14, p. 140).

- MDP = mean depth of penetration [mils] = (volume loss) / (specimen face area)

- 1 mil = 25.4 μm

- The tip diameter was 13.9 mm (p. 33) rather than the standard 15.9 mm.

- The MDP for single crystal tungsten was 0.025 mils/hour (table 29, p. 201).

- In addition to water tests, cavitation tests were also conducted in high temperature lead-bismuth, mercury, and lithium.

- Other materials were also tested.

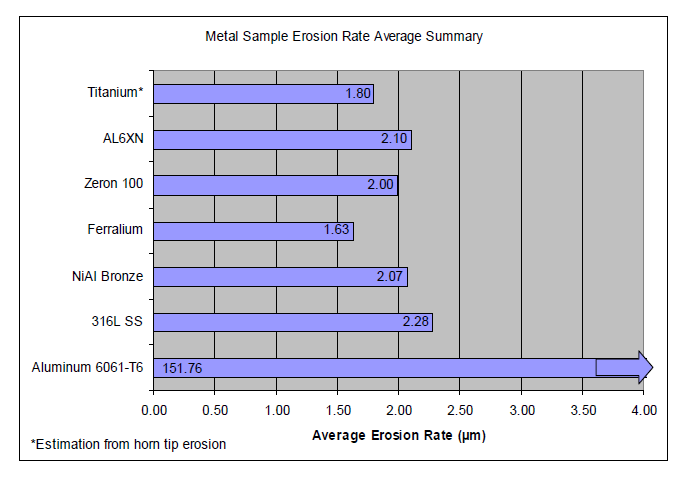

Light

The following chart is from Light[1] (p. 40).

|

|

|

- The "erosion rate" is the maximum rate of erosion which is defined as the slope of the straight line that best approximates the linear (or nearly linear) steepest portion of the MDE (mean depth of erosion) curve (occurring after the incubation period) and is expressed in micrometers per hour. This is the slope of the "maximum rate line" of figure A4.

- The tip diameter was 10.5 mm (p. 65) rather than the standard 15.9 mm.

- With the exception of titanium, all materials were tested by the "stationary specimen" method whereby the specimen was fixed within the liquid container and the vibrating horn tip was placed close to it (0.50 mm in this case). The cavitation from the horn then acted to erode the stationary specimen. (p. 27)

For titanium (Ti-6Al-4V, p. 26) the test specimen was a tip attached to the end of the horn. Since this method and the "stationary specimen" method may give different results for the same material, it may not be proper to compare the titanium results to the other results. (See ASTM cavitation erosion specification G32‑10, pp. 3, 17) - 316L stainless steel was used as a reference material since it is often used in cavitating environments including turbine blades, valve and piping components, .

- AL-6XN (UNS N08367) is an austenitic stainless steel that has high resistance to chloride pitting (e.g., sea water) and other very corrosive environments. Knapp[1] (p. 351) notes, "It is logical that cavitation and corrosion should be mutually reinforcing so that the resulting damage is often much greater than the sum of the two, if each acted alone." Thus, compared to other materials this material (or similar) might exhibit relatively better cavitation performance if tested in a corrosive environment.

- Ferralium is a high strength, corrosion resistant stainless steel produced by Langley Alloys of Staffordshire England. Zeron 100 is a similar grade of material produced by Weir Materials and Foundries in Manchester England.

- NiAl bronze is specifically used for propellers (liquid applications) because of its resistance to cavitation erosion.

Hielscher

Hielscher (p. 6) reports that 1 mm of the sonotrode erodes within 1000 hours when operated at maximum amplitude. Although the sonotrode material and test amplitude are not explicitly stated, the accompanying text likely indicates that the material is titanium and the amplitude is 250 microns (presumably peak-to-peak). (This test was not conducted according to ASTM G32-10.)