Threaded fasteners

Materials

Titanium bolts and studs are available from

- http://www.revolutionmaterials.com.au/fasteners.php

- SPS

Threads

Thread forms

"Standard" threads don't specify a radius at the root of the thread (although small radii will be present due to normal machining practice). These "sharp" roots cause significant stress concentrations which lead to reduced fatigue lives (especially in notch sensitive materials like heat treated steels). Higher hardness ==> larger radius.

In order to improve fatigue life, external threads for studs and screws can specify a root radius. The thread form is specified as UNR or UNJ. Table 1 shows the allowed min/max radii for these threads, together with comparator photographs.

| Table 1. Thread root radii (min/max) |

|

| Thread form |

Min. root radius |

Max. root radius |

Comparator

photograph |

| Standard |

No specification |

No specification |

|

| UNR |

0.10825p |

0.14434p |

|

| UNJ |

0.15011p |

0.18042p |

|

|

Table notes —

- p = thread pitch

- The max. root radius is also the nominal root radius (SPS Technologies (3), p. IV-8).

- Reference for UNR thread form — Kanter (1), p. M-19

- Reference for UNJ thread form — Military Specification MIL-S-8879C, p. 27

- Comparator photographs are from SPS Technologies (3), p. IV-9.

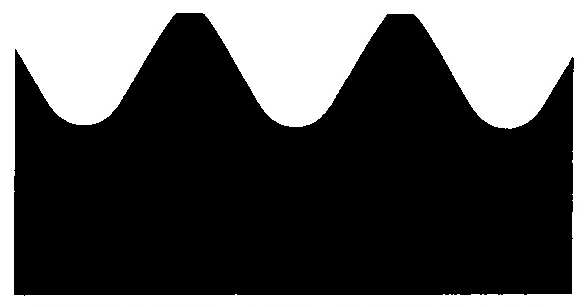

Figure 2 shows the effect on fatigue (Culp (0)). At the runout at 10e6 cycles, the UNR thread form increases the endurance stress from 20 ksi to 40 ksi (+100%) while the UNJ thread form increases the endurance stress from 20 ksi to 50 ksi (+150%).

|

|

| Figure 2. Effect of thread form on fatigue |

|

Important — Fatigue depends on many factors. Therefore, the fatigue graphs presented here should not be used for design purposes.

Thread fabrication

External threads

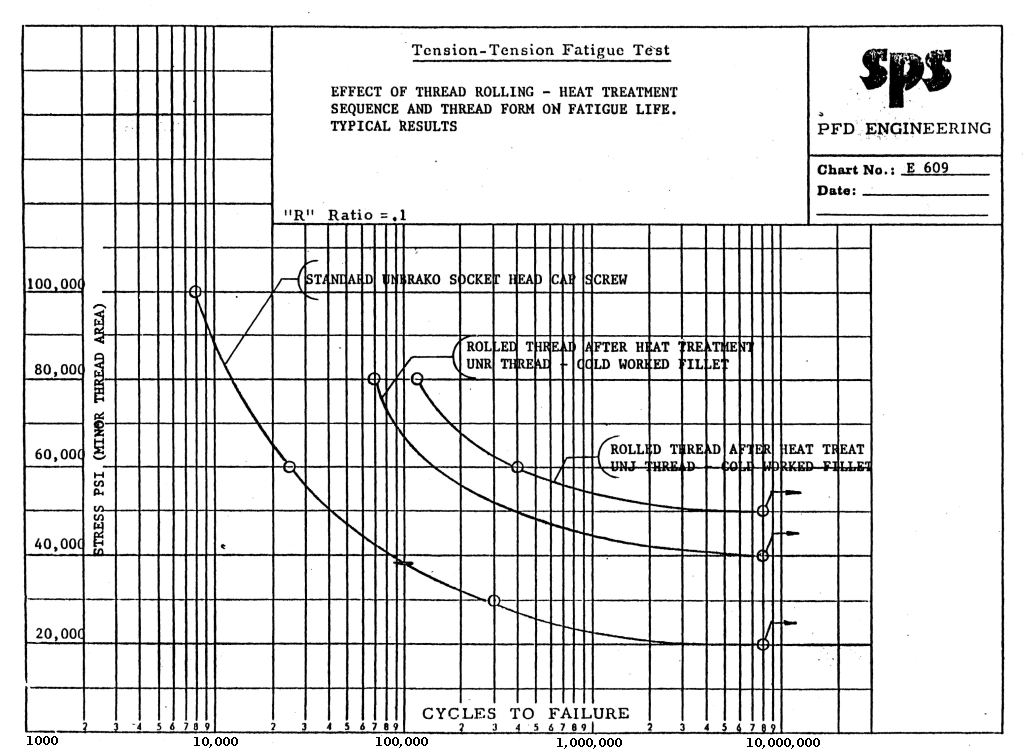

External threads are fabricated by rolling between dies (for large production lots such as standard socket set screws) or cutting (for small production lots). Cutting removes material and interrupts the natural grain flow. Rolling, which displaces material rather than removing it, gives better fatigue life because it preserves the natural grain flow.

Rolling also improves fatigue strength by inducing compressive stresses at the thread root. However, these compressive stresses are lost if the rolling is followed by heat treatment. Therefore, the threads should be rolled after heat treatment. The disadvantage is that the rolling dies wear more quickly because of the material's increased hardness.

Figure 4 shows the advantage of rolling after heat treatment. At the runout at 10e6 cycles, rolling after heat treatment increases the endurance stress from 20 ksi to 80 ksi (+300%).

Internal threads

Internal threads are needed to accommodate the studs that connect adjacent resonators, for tips, and for the transducer's stack bolt. Because of their high stress concentration, threads can be sites of fatigue crack initiation. Threads are typically fabricated by tapping although special thread forms (e.g., radiused root) may require single point turning.

Cold-forming taps

Conventional taps remove material by the cutting action of the tap. However, cold-forming taps have a wedging tooth profile that displaces material rather than removing material. This plastic cold working induces compressive stresses at the thread root while maintaining grain flow and also can leave a radius at the thread root (figure 4b). (Note, however, that the compressive stresses are removed if the part is heat treated after tapping.) Additionally, the thread surface is smooth and burnished (Destefani (1)).

These advantages improve fatigue life. Resistance to static stress also increases. For example, Sağlam (1) (p. 214) reports a 23% increase in average maximum tensile load for M12x1.75 threads with 10 mm of engagement.

Cold-forming taps can be used in softer materials — those with tensile strengths up to 1400 MPa (Emuge (1), p. 19) — including aluminum, Ti-6Al-4V, and some steels (Emuge (1), p. 14).

Compared to conventional tapping, cold-formed tapping can be faster with longer tool life. Also, chip removal isn't a problem because no chips are formed. However, because of the high friction involved in the forming process, special tap coatings and lubricants may be needed (Emuge (1), pp. 4, 24).

|

|

| Figure 4a. Conventional cutting tap (left) and cold-forming tap (right) |

|

|

|

Figure 4b. Cold-formed thread versus cut thread

(Emuge (1), p. 18) |

|

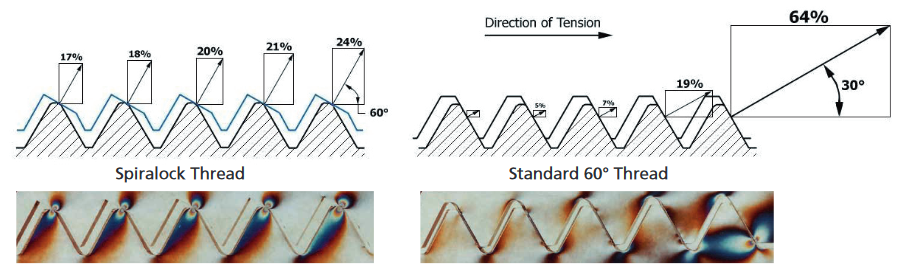

Asymmetric threads

In conventional threads the first few threads absorb the majority of the load; the remaining threads contribute little (the right panel of figure 4c). The load can be more evenly distributed by using an asymmetric thread such as the Spiralock.

|

|

| Figure 4c. Spiralock threads — load distribution |

|

Studs

Materials and sizes

Studs are generally made of steel but sometimes of titanium.

Common sizes are 1/2-20, 3/8-24, and M8. Other sizes may be used depending on a manufacturer's preferences.

Bottomed versus unbottomed studs

Studs should not be bottomed in the stud hole because this causes high static stress at the bottom of the stud hole (particularly a problem for aluminum horns) and also causes heating. Culp (0) conducted tests on the effect of stud bottoming on a 40 kHz high gain half-wave cylindrical aluminum horn which was attached directly to a transducer. The stud was M8 steel and was secured in the horn with Loctite grade 242 thread lock. The bottomed stud was tightened very "tight" (no specified torque) into the bottom of the threaded hole; the unbottomed stud was backed off 1/2 turn from the bottom. Figure 4d shows the results where each curve is the average of three separate tests. (The data scatter within each set of three tests was small.)

The same horn and transducer stack were used for all tests. During the tests the stack wasn't cooled. The temperatures were measured with a thermocouple on the transducer's aluminum front driver just next to the transducer-horn joint. Between each test the stack was allowed to cool to room temperature. At that time the horn was disassembled from the transducer and the joint was re-lubricated before reassembly; this reduced the possibility that a corrupted joint might contaminate the results.

Figure 4d clearly shows the temperature advantage of an unbottomed stud. For corroboration, the average measured power loss for the stack with the unbottomed stud was 37% lower than the bottomed stud. (Note — The unbottomed stud reduced the horn's amplitude by 6.3%. FEA predicts a reduction of 5.2%.)

|

|

| Figure 4d. Effect of stud bottom contact on joint temperture |

|

Also see Integral studs and Washer studs.

If the stud must be bottomed for some reason, table 2 shows the recommendations of several ultrasonic companies.

| Table 2. Bottomed studs — torques |

|

| Stud size |

Ultrasonic company |

Recommended

torque (Nm) |

| 1/2-20 |

Branson Ultrasonics |

51 |

| Dukane |

1.4 - 2.0 |

| Sonics & Materials |

61 |

| 3/8-24 |

Branson Ultrasonics |

33 |

| Dukane |

1.4 - 2.0 |

| M8-1.25 |

Branson Ultrasonics |

7.9 |

| Dukane |

1.4 - 2.0 |

|

Table notes —

- References —

- Branson Ultrasonics (2), p. 4

- Dukane —

- Sonics & Materials — Model 1098 Press (p. 13)

- The large differences in recommended torques for the same stud size indicate some fundamental misunderstanding of the torque requirements.

Anti-rotation means

Some means must be used to prevent an installed stud from rotating when the associated joint is tightened or loosened and to prevent the stud from migrating within the threaded hole when ultrasonics are activated.

Threadlocking adhesives

A threadlocking adhesive is applied to threads and is typically designed to cure anaerobically after the threaded parts have been assembled. Loctite® is one prominent brand although many others are available.

Branson uses studs with knurled ends that are bottomed, together with Loctite® 290 (where appropriate). A company that makes ultrasonic metal welders uses unbottomed studs with Loctite® 243 (Culp (0)). Table 3 shows a comparison of these Loctite® grades.

| Table 3. Loctite® torque performance |

|

| Loctite® grade |

Breakaway torque

(Nm) |

Prevailing torque

(Nm) |

Breakloose torque

(Nm) |

| 243 |

20 |

7 |

24 |

| 290 |

10 |

29 |

30 |

|

Table notes —

- The torque values are for M10 steel nuts and bolts. See the above linked data sheets.

- Breakaway torque = for an unbottomed fastener, the torque required to break the threadlock bond

- Prevailing torque = for an unbottomed fastener, the torque required to continue to rotate the fastener after the threadlock bond has initially been broken

- Breakloose torque = for a bottomed fastener, the torque required to unbottom the fastener

Application to an unbottomed stud

The following procedure is recommended when using a threadlocking adhesive with an unbottomed stud —

- Clean the stud and stud hole thoroughly to remove any oil and contaminates. Otherwise, the thread locking compound will not adhere properly. (Some threadlocking adhesives are somewhat tolerant of oil and contaminates. Consult the manufacturer.)

- Apply the threadlocking adhesive to the resonator threads.

- Hand bottom the stud in the hole and then back off 1/2 turn.

- While preventing the stud from rotating, run a jam nut over the exposed stud until the nut contacts the resonator. Securely tighten the jam nut. (Note — the faces of the jam nut must be very perpendicular to the jam nut's threads. This will assure that the stud remains perpendicular to the resonator's stud surface until the thread locking compound has cured. If a correctly machined jam nut is not available then a threading die works well.)

- After the threadlocking adhesive has cured, remove the jam nut.

- Remove any exposed uncured threadlocking adhesive.

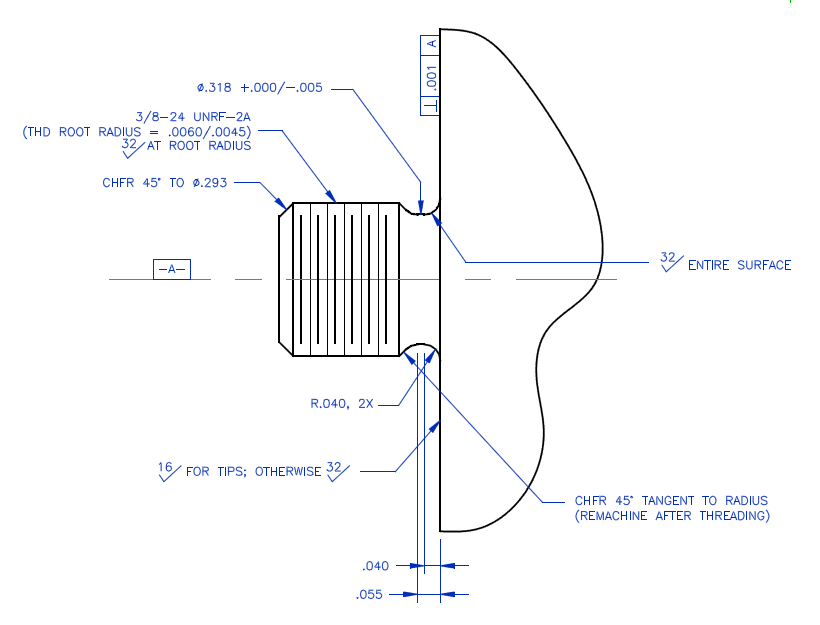

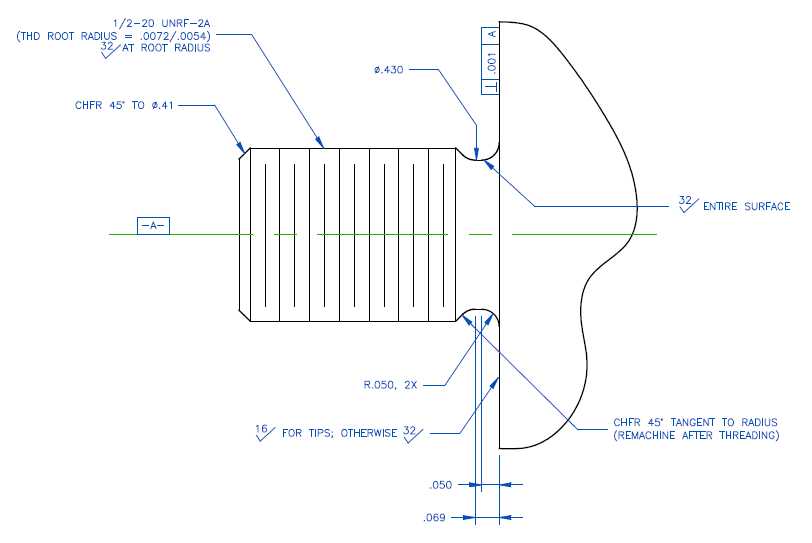

Integral studs

An integral stud is machined as an integral part of a resonator. It is used on tips and often used on small diameter medical probes. It eliminates the need for a separate stud and associated assembly, assures maximum perpendicularity to the associated joint, and minimizes frictional loss and stress that may be caused by a separate stud. It also allows control of the thread form — e.g., UNR or UNJ threads with larger root radii can be specified, if desired. This may be appropriate, for example, for steel horns where the threads may be notch sensitive after heat treatment.

|

|

Figure 5. 3/8-24 integral stud with class R threads

(Culp (0)) |

|

|

|

Figure 6. 1/2-20 integral stud with class R threads

(Culp (0)) |

|

Integral studs are most suitable for resonators with relatively small lateral dimensions. They are not suitable for resonators with large lateral dimensions since significant material must be machined away in order to create the stud. They also may not be suitable for aluminum resonators since the aluminum thread material may not be sufficiently strong.

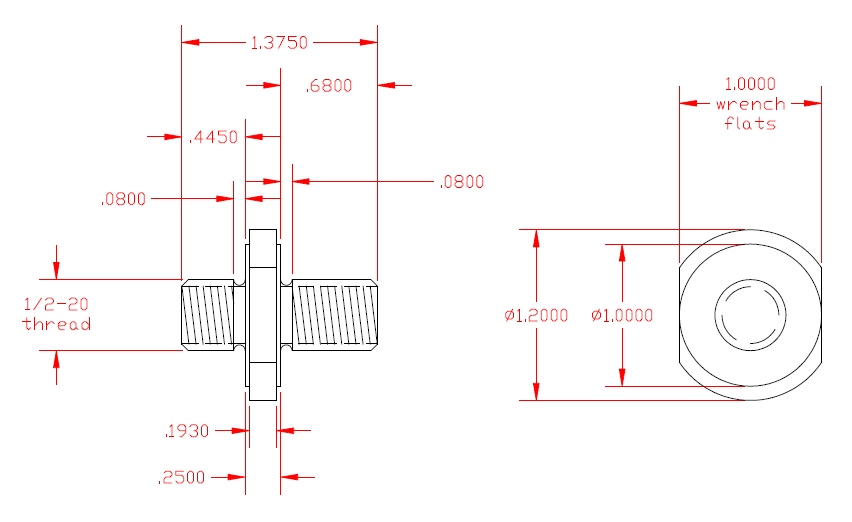

Washer studs

Washer studs replace conventional studs. Washer studs are made of titanium and are typically used between the booster and horn or between the master horn and tip horn. These have been reported to be effective in certain unspecified situations, possibly due to the reduced joint contact area or because they don't bottom. At least one of the connected resonators must be tuned to accommodate the washer thickness. Washer studs have been used by Branson Ultrasonics.

|

|

Figure 7. Washer stud (1/2-20 threads for 20 kHz)

(Culp (0)) |

|

|

|

Figure 8. Washer stud drawing (1/2-20 threads for 20 kHz)

(Culp (0)) |

|

Effect on horn stress and amplitude

Thread inserts (Helicoil, etc.)