Electrical Discharge Machining (EDM)

Contents

Electrical discharge machining (EDM) is a process where metal is removed using electrical discharges (sparks) to melt and evaporate the metal. The sparks are generated between a conductive electrode and the metal part, both of which are immersed in a dielectric fluid. The dielectric fluid acts as an ionization medium for the sparks and also flushes the sparked material away from the cutting region. The sparks are pulsed at high frequency. EDM is generally limited to conductive materials. Two common types are wire EDM and sinker EDM.

Wire EDM (WEDM)

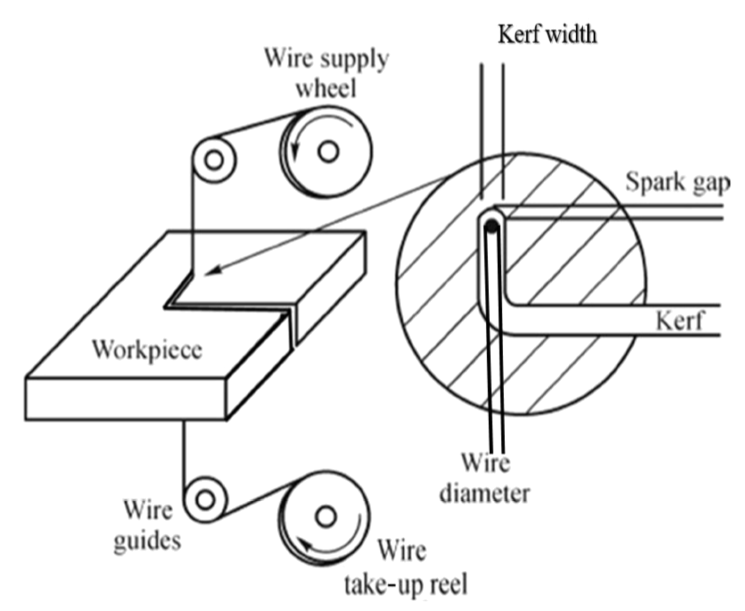

In wire EDM a thin metal wire is fed continuously between two spools (figure 1). The wire is kept under constant predefined tension to minimize lateral vibration of the wire. As the wire is fed it also traces a path on the part that is being machined. The wire diameter is typically 0.3 mm for roughing and 0.2 mm for finishing. Brass wire coated with zinc is preferred for machining titanium (Pramanik [1], pp. 2‑3).

|

|

|

Wire EDM has been suggested (and tried) for machining slots in horns. However, there are several disadvantages compared to conventional machining —

- Wire EDM may be significantly slower.

- Many shops don't have wire EDM equipment so the horns must be sent to specialty shops. This increases the cost and delivery time.

- Wire EDM can significantly reduce the resonator's fatigue life.

- For titanium, very high spark temperatures are required (~20000 °C) (Pramanik [1], p. 2). This damages the electrode wire. The damage increases the longer the wire is exposed to the part. Hence, while the wire will be in good condition as it enters the part, it will be in relatively poorer condition as it exits the part on the opposite side. The damage increases as the part thickness increases due to the wire's increased exposure time and also reduced flushing ability. Thus, the machining is cleaner at the top of the part and comparatively dirtier at the bottom (Pramanik [1], p. 2). Additionally, the damage to the wire increases the probability of wire breakage. Pramanik [1] reports that wire breakage in titanium is "very frequent" (p. 3). These problems would likely be present when machining slots in large block horns (e.g., up to 250 mm thick).

Cutting speed

Cutting speed is somewhat difficult to characterize since it depends on the many process parameters and the desired outcome, especially the surface finish and fatigue performance. In general, however, cutting speeds are low compared to conventional machining. After optimized the parameters for cutting 10 mm x 10 mm x 15 mm annealed Ti-6Al-4V, Gupta [1] reported a maximum speed of 1.75 mm/min. Based on this cutting speed, a 100 mm long x 10 mm wide slot (= 220 mm periphery) for a 20 kHz titanium horn would require approximately 2 hours.

Pramanik [1] (p. 4) reported that the surface roughness increased almost linearly with cutting speed. At 2.65 mm/min the surface roughness was 2.44 μm; beyond this the surface roughness detiorated drastically. At 2.65 mm/min the same slot as above would require approximately 1.4 hours.

Fatigue

For fatigue, two important machining considerations are surface roughness and residual tensile stresses. The results of conventional machining are largely controlled by tool speeds, feeds, tool geometry and material, and cutting fluid. These parameters are generally well understood for many part materials. In contrast, EDM process parameters include pulse on-time, pulse off-time, peak current, wire feed rate, wire tension, spark gap voltage, electrode (wire) type, dielectric fluid, flushing pressure of dielectric fluid, and servo feed rate (Rao [1], p. 2). Pulse shape and frequency also affect performance (Pramanik [1], p. 5). Many of these parameters are still under investigation for particular part materials. The following provides some information but is certainly not comprehensive. (Rao summarizes many EDM studies as of 2014.)

During EDM, high heat is generated on the part's surface due to sparking. Some of this heat is used to melt and vaporize the part's material. The remaining heat is either drawn away by the dielectric fluid or conducted into the part. Because titanium has poor conductivity, the temperature in the machined surface is considerably higher than below the machined surface. This causes intense heat in a thin layer of the machined surface. At the same time this layer is being quenched by the dielectric fluid. Thus, the properties of the machined surface change significantly compared to the bulk material. (Pramanik [1], p. 2) Of course, the resulting surface topography differs from that of conventional machining; also, surface microcracks may form.

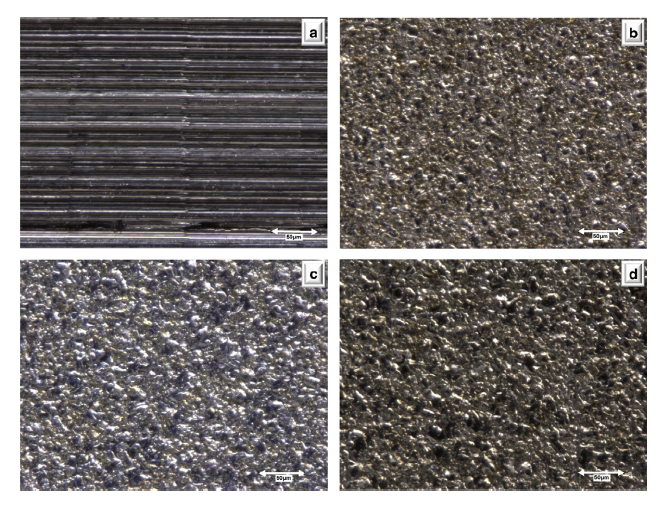

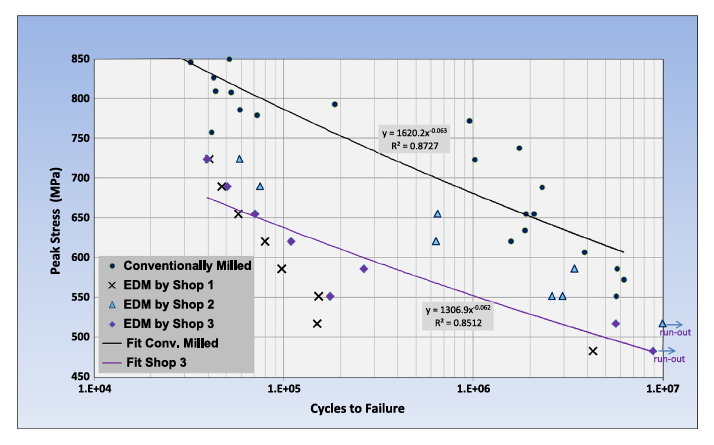

Mower [1] ran tension fatigue tests (\( R \)= 0.1) on Ti-6Al-4V using standard ASTM test specimens . The edges of these specimens were either conventionally machined with a carbide end mill or were EDM'd by three independent shops to their best surface finish using their best optimized (proprietary) EDM parameters (see figure 2). The results of fatigue tests at 10 Hz are shown in figure 3. Using the data from shop 3, Mower found that the fatigue strength of the EDM'd specimens was reduced to 80% of the conventionally-milled specimens. (Interestingly, shop 3 had the worst surface finish but had intermediate fatigue performance between shop 1 and shop 2. Thus, surface finish by itself does not necessarily correlate to fatigue performance.) It should be remembered, however, that these specimens were very carefully prepared for optimal surface finishes; real-world machining would produce somewhat different results although the trends would likely be similar. (Note — Mower found that the negative effects of EDM could be reversed by electropolishing and/or shot peening. However, this again increases the cost and delivery time.)

Yeo found similar problems with wire EDM of 4340 steel. Both Mower and Yeo found that the nominal fatigue performance could be restored by bead blasting or shot peening.

|

|

|

|

|

|

Keyhole slots

Keyhole slots can only reasonably be machined with wire EDM. However, even without the disadvantages of wire EDM, keyhole slots are not recommended because of they have inherently higher stresses than conventional slots.

Sinker EDM

For rigid-mount boosters, sinker EDM has been used to machine the deep groove that separates the decoupling band from the booster body. Sinker EDM could also be used to machine details on a horn's face where the ultrasonic stress is low. However, conventional machining would typically be faster and less expensive.