Steel

Contents

- Material selection

- Fatigue

- Loss

- Machinability

- Known steels

- Figures

- Figure 1. Steel metal welding horn with integral welding surface

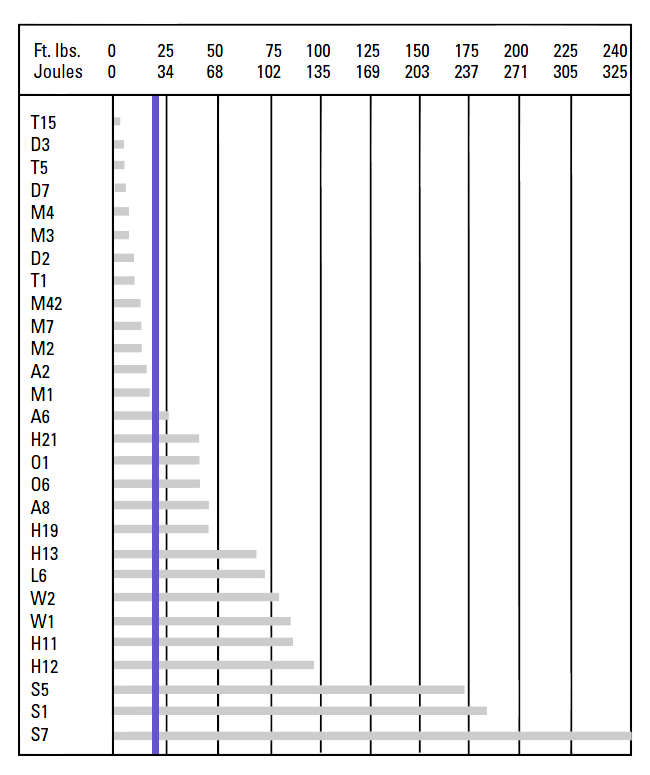

- Figure 2. Power loss of acoustic materials at 15 kHz

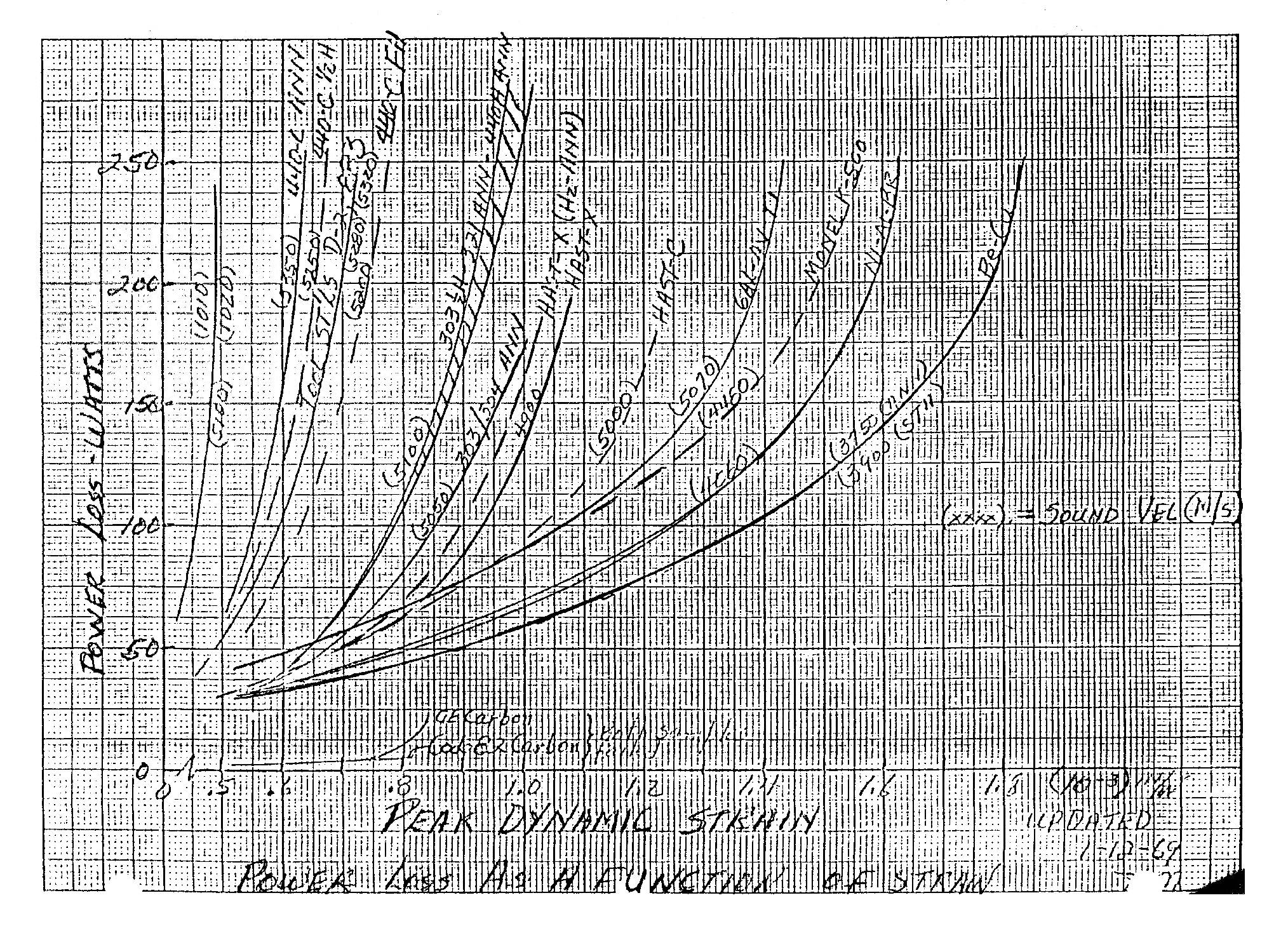

- Figure 3. Test setup to measure loss (Aeroprojects)

- Figure 4. Effect of grain size on internal friction Q-1

- Figure 5. Comparative performance of CPM® steels

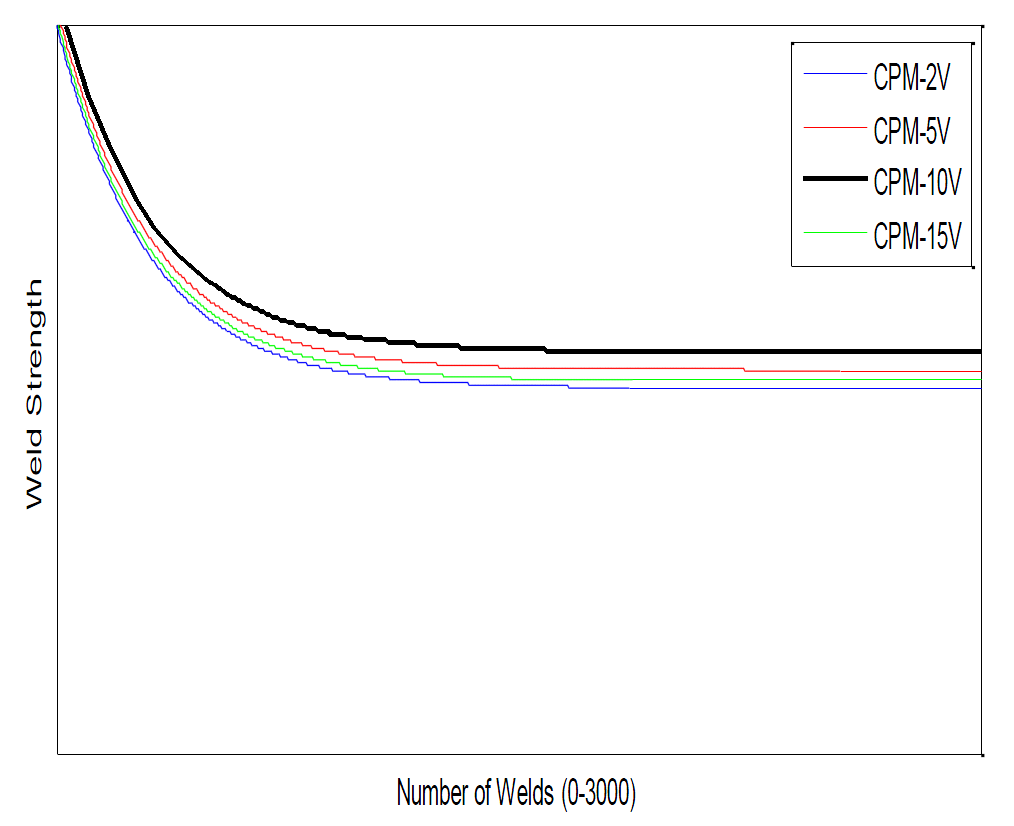

- Figure 6. Metal welding tests with CPM® horns

- Figure 7. Tool steel machinability rating relative to W1 steel

- Figure 8. Comparative machinability of frequently used stainless steels and their free-machining counterparts

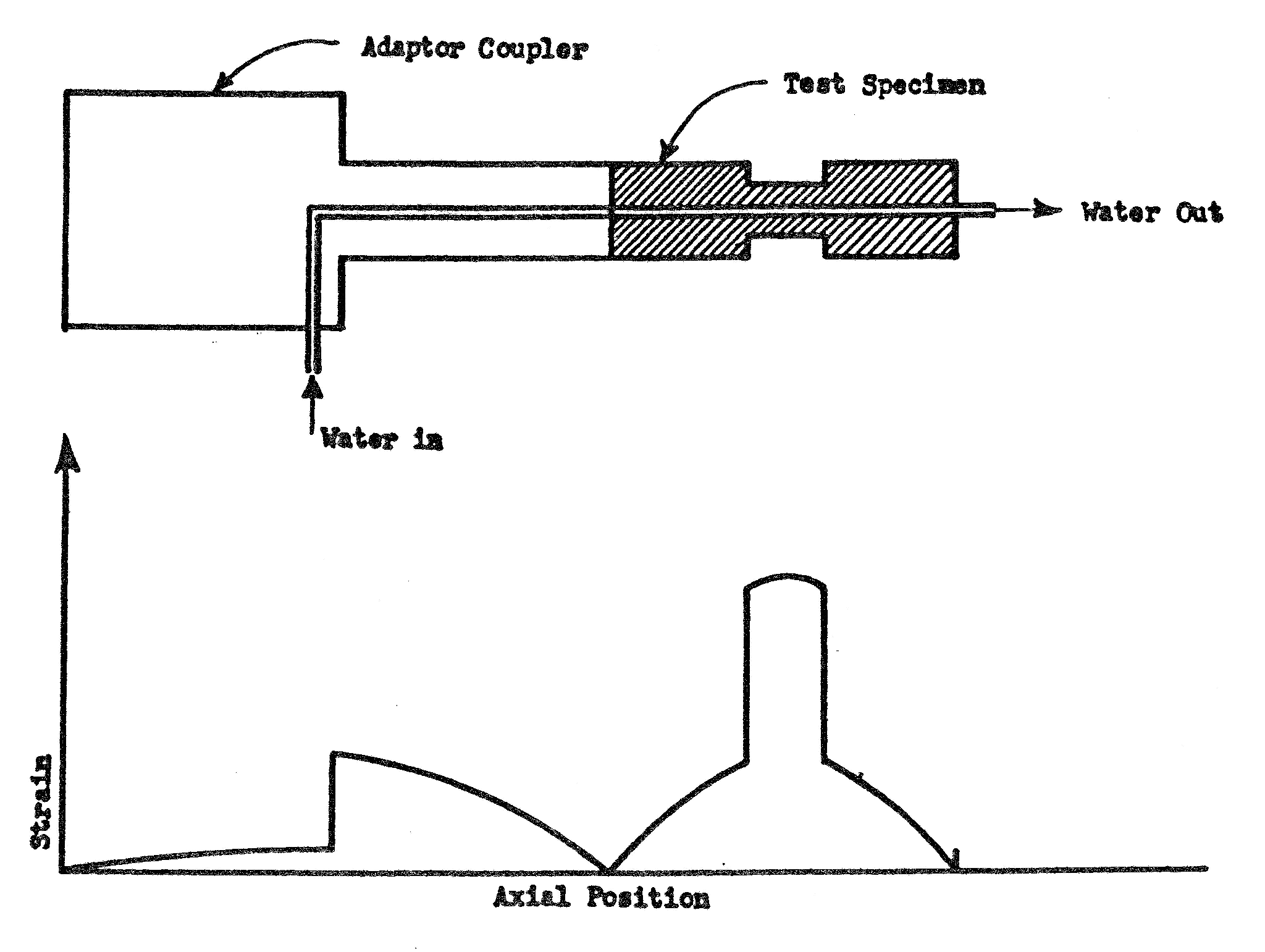

- Figure 9. Shock resistance comparison chart

- Tables

Steels are used for ultrasonic resonators when wear resistance and/or impact resistance are required. For example, they have been used in for metal welding horns (where the welding tip surface is integral to the horn — figure 1) and for horns used for insertion.

|

|

|

Material selection

Unlike titanium and aluminum, selecting an appropriate steel is complicated by several factors.

- There are thousands of different steels. Some of these have just slightly different alloy compositions but with big impact on performance.

- For heat-treatable steels there are many heat-treat variables that affect performance, for example the temperatures and durations (for preheating, heat treating, quenching, tempering), the surrounding media (air, inert gas, salts), etc. These may vary even for a specific steel, depending on the desired final properties.

- Although steels work well at relatively low strains, the loss can increase dramatically at higher strains (see figure 2). Conventional (handbook) property listings don't specify loss properties because 1) loss isn't important for conventional (non-ultrasonic) applications, 2) loss is not a fixed value but varies with the strain, and 3) loss depends on the heat treatment. Instead, loss must be determined by actual ultrasonic tests for each material and heat treatment at the expected strain levels. Although low loss is important, other desired properties such as wear and notch sensitivity (e.g., for threads) must also be considered.

Fatigue

See a general discussion of fatigue. In addition, the following are specific to steel.

Notch sensitivity

A desirable property of acoustic materials is that they should have low fatigue notch sensitivity (i.e., the endurance strength with a notch should be be nearly equal to the same material without a notch). This is important, for example, in fatigue of threads.

Two similar tests that determine impact notch sensitivity are the Charpy and Izod. In these tests a heavy pendulum strikes and breaks a notched test specimen. The change in potential energy of the pendulum (before and after the strike) indicates the impact notch sensitivity. Figure 9 shows the impact shock resistance of various steels based on Charpy "V" notch test results. (Bryson[1], p. 139) Note — the vertical blue line has been added. It represents the Charpy "V" notch results for Ti-6Al-4V (annealed and STA sheet and bar). (See TIMET[1], figure 26, p. 18.) (Because titanium is orthotropic, its shock resistance depends on the test direction.)

|

|

|

Unfortunately, there may be little correlation between the impact notch sensitivity and fatigue notch sensitivity. As Yen[1] (p. 12) relates, "It is generally believed that hard steels are more notch-sensitive than soft steels either in a fatigue test, a static tension test, or an impact test. Some test data have indicated that the stronger the steel the lower is the Charpy impact value and the greater the fatigue notch-sensitivity; hence, one might infer the possibility of a relation between impact values and fatigue notch-sensitivity. However, no direct correlation between these two types of test has ever been reported and some contrary evidence indicating that there is no reason to expect a correlation has been presented".

Threads

Steel horns are known to fail in the threads.

Loss

Figure 2 shows the loss for a number of materials, including several steels. (This data, from Aeroprojects 1969, was conveyed to Culp[0] by Maropis[0].) The experimental setup is shown in figure 3. The loss was determined from the increase in temperature of water that flowed through the center of a highly stressed 15 kHz horn. Note that the losses are only valid for the particular frequency and sample shape. However, comparisons among the various materials are still valid. Table 1 shows the best determination of the hand-written notes from figure 2.

Notes —

- All steels are more lossy than Ti-6Al-4V and many are substantially more lossy.

- For 440-C steel, the wave speed decreases from 5350 m/sec to 5200 m/sec (-2.8%) as its condition changes from annealed to full hard. D2 exhibits a similar trend.

|

|

|

|

|

|

Effect of grain size

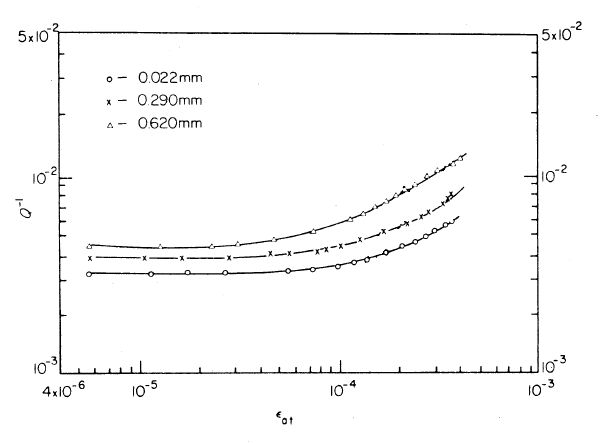

Puskar[1] tested a low carbon unalloyed steel at 23 kHz to determine the internal friction Q-1. (Note — loss varies directly with the internal friction which is the reciprocal of the quality factor Q.) The results are shown in figure 4 where the horizontal axis is the total strain amplitude \( \epsilon_{at} \). (It is believed that this is the peak strain rather than the peak-to-peak strain although this is not explicitly stated.)

As the grain size is reduced (likely due to the heat treatment process) the internal friction is also reduced. It is likely that there is some point at which further reduction in grain size does not result in further reduction in internal friction. However, this cannot be deduced from the given data.

Also, there is a critical strain \( \epsilon_{c} \) at which the internal friction starts to increase (i.e., the curves trend upward). This critical strain depends on the grain size. For example, for a grain size of 0.620 mm \( \epsilon_{c} \) is 7.3e-5 whereas for a grain size of 0.022 mm this increases to 1.3e-4. Thus, considering only the effect of loss, this fine-grained material could be driven at substantially higher amplitudes than the same coarse-grained material. The same is likely true for other steels.

|

|

|

Machinability

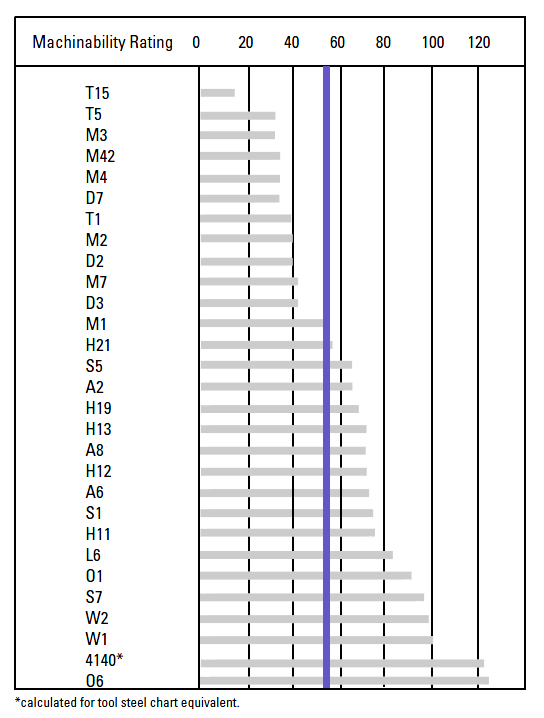

Figure 7 shows the machinability of various steels relative to W1 (a water hardening steel) at 100, where the machinability of W1 equals 40% on the AISI B1112 scale. (Bryson[1], p. 141. Note — the vertical blue line has been added. It represents the machinability of Ti-6Al-4V which is 22% on the AISI B1112 scale (Carpenter[1], p. 6) or 55% relative to W1.)

|

|

|

Known steels

The following steels have been used in some manner for ultrasonic resonators. The comparative merits of these steels are only partially known.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Table notes —

- The thin-wire wave speed is a calculated value.

- Data that are measured or calculated from ultrasonic tests are in bold type. Except as noted, these are from Culp[0]. Corresponding nominal "handbook" data (typically from manufacturer's data or matweb.com) are in parentheses.

- Unless otherwise stated, all properties are at room temperature.

Table references —

- FX Temper 2 tool steel —

Poisson's ratio was measured with tensile tests on three samples (25.4 mm square).

The density was measured in the laboratory.

- Young's modulus was measured with a 40 kHz ultrasonic full-wave/half-wave test (one sample). The test sample was Ø19.1 mm.

- Young's modulus was calibrated from FEA of a 40 kHz 2-slot bar horn (one sample each).

- Young's modulus was calibrated from FEA of a 40 kHz unslotted flatted-cylindrical horn.

- Al-Sarrif[1] — 20.8 kHz metal welding horn (FEA calibrated); 20 microns p-p (p. 68); 5 microns p-p input. The integrated welding tip was hardened to HRC 55-60 (p. 54); it is not known if this applied only to the welding tip or to the entire horn.

- Stanasel[1] — 20 kHz metal welding horn (figure 1) for welding cables for the automotive industry, FEA analysis. Stanasel gives partial horn dimensions.

Notes for the following materials —

- Except as specifically recommended below, see Bryson[1] for suggested conventional heat treatments (without consideration of ultrasonic requirements). Consult your heat treater who may have additional recommendations.

- Unless otherwise stated, the "Characteristics" below are from the manufacturer's data or, alternately, from matweb.com.

- The listed applications are those which are known or available through the literature. The listed applications are not comprehensive and in many cases a particular material could easily be used for multiple applications. Also, some applications may be for prototype development for which the chosen material may have been a matter of convenience, rather than an attempt for an optimized material.

Tool steels

AISI A2 tool steel

Characteristics — "High hardenability, high degree of dimensional stability in heat treatment, good wear resistance, fatigue life, toughness, and deep hardening qualities."

Applications — Ultrasonic processing of petroleum products. See Gunnerman's patent[2], paragraph 0013. (Note — The patent specifies "2‑A tooling steel". However, no such material could be identified. From the specified composition (paragraph 0013) the material is likely A2.)

AISI D2 tool steel

Characteristics — An air-hardening, high carbon, high chromium tool steel, heat treatable to HRC 60-62. It has excellent abrasion resistance due to a large volume of carbides in the microstructure.

Applications — Ultrasonic metal welding tips, plastics sealing horns, inserting horns.

AISI M2 tool steel

Characteristics — A tungsten-molybdenum high speed tool steel with excellent combination of wear resistance, toughness and hot hardness.

Applications — Ultrasonic metal welding horns.

Vertex

Characteristics — "TLS Vertex tool steel is a versatile, high-chromium, air-hardening tool steel that is characterized by a relatively high attainable hardness and numerous, chromium-rich alloy carbides in the microstructure. These carbides provide good resistance to wear from sliding contact with other metals and abrasive materials. The primary alloy carbides in Vertex are smaller than the large chromium-rich alloy carbides which are characteristic of D2 tool steel. These smaller carbides result in better impact toughness and superior fatigue properties compared to D2.

The molybdenum addition in Vertex enhances the hardness of the alloy carbides, and more significantly, provides superior secondary hardening response compared to D2. Therefore, unlike D2, Vertex can be tempered at higher tempering temperatures yet still attain a hardness in excess of 60 Rockwell C. Because of the higher secondary hardness, Vertex exhibits superior wear resistance compared to D2 tempered at the higher tempering temperatures, as well as the superior toughness that is the result of the high-temperature tempering." (Vertex data sheet)

Originally manufactured by Timken Latrobe Steel; now Latrobe Specialty Steels Co.

Heat treatment (suggested by Latrobe). Final hardness should be ~HRC 56.

- Preheating. Preheat at a rate not exceeding 400 °F/hr (220 °C/hr) to 1150 - 1250 °F (621 -677 °C), equalize, then heat to 1400 - 1450 °F (760 - 788 °C).

- Austenitizing. Heat slowly from preheat. Furnace or Salt: austenitize at 1850 °F (1010 °C)

- Quenching. Air or pressurized gas. Cool to 150 - 125 °F (66 - 51 °C).

- Tempering. Temper immediately after quenching. Heat to 1050 °F (565 °C). Hold at temperature for 1 hour per inch of thickness (2 hours minimum), then air cool to ambient temperature and repeat.

FX Temper 2

Characteristics — "A moderate level of alloys nickel (Ni .80%), chromium (Cr 1.15%) and molybdenum (Mo .5%) provides this die steel with a good balance between fracture toughness and wear resistance at the widely used Temper 2 hardness (38-42 HRC)."

Manufactured by Finkl Steel. See data sheet.

Applications — Ultrasonic atomization of solder (Culp[0]).

Stainless steels

AISI 630 (17Cr-4Ni; 17-4 PH) stainless steel

PH refers to precipitation hardening.

Characteristics — A martensitic precipitation/age-hardening stainless steel offering high strength and hardness along with excellent corrosion resistance.

Applications — Ultrasonic dental tips.

AISI 304 stainless steel

Characteristics — Better corrosion resistance than Type 302. Resists most oxidizing acids and salt spray.

Applications — Sonochemistry.

Loss measurements

Table 3 shows loss measurements for several stainless steel materials (Culp[0]). Ony a single sample of each material was tested. Note that the loss for the 3xx series is significantly lower than the 4xx series even though the hardnesses are lower.

|

||||||||||||||||||||||||||||||||||||

|

Table notes —

- Materials —

Inspection certificates with hardness values were provided.

Approximate equivalent HRC hardnesses are shown in ( ).

Ti-6Al-4V data are provided for comparison. - Horn dimensions —

Output diameter = 17.5 mm

Input diameter = 38.1 mm

Rear shoulder length = 25.4 mm

Transition radius = 38.1 mm

3/8-24 step stud (unbottomed) - Test equipment —

Frequencies — Branson A200A (low amplitudes)

Amplitudes — Fotonic Sensor

Power — Clarke-Hess watt meter (the loss includes that of the driving transducer)

Power supply — Sonics & Materials 600 watt Vibracell set at 40%

Transducer — same for all tests

Machinability

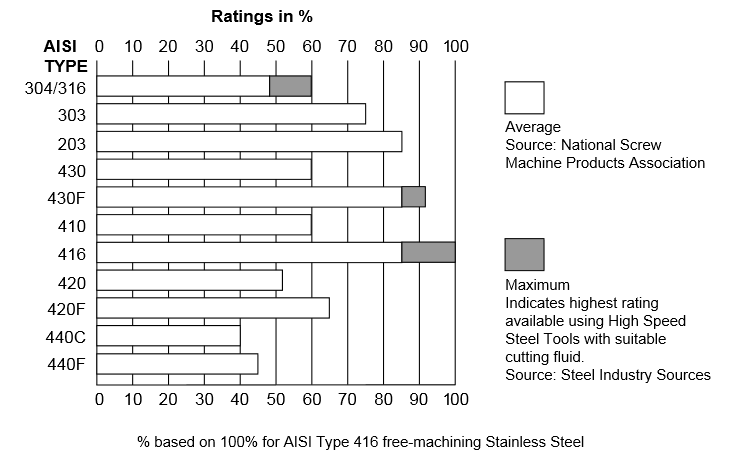

Figure 8 (SSINA) shows the machinability for various grades of stainless steel (higher values are better).

|

|

|

Powder metallurgy steels

CPM® tool steel

CPM® refers to the Crucible Particle [powder] Metallurgy process (Crucible Industries) with vanadium carbide between 10% and 18%. See Haswell's[1] patent (1981).

V series

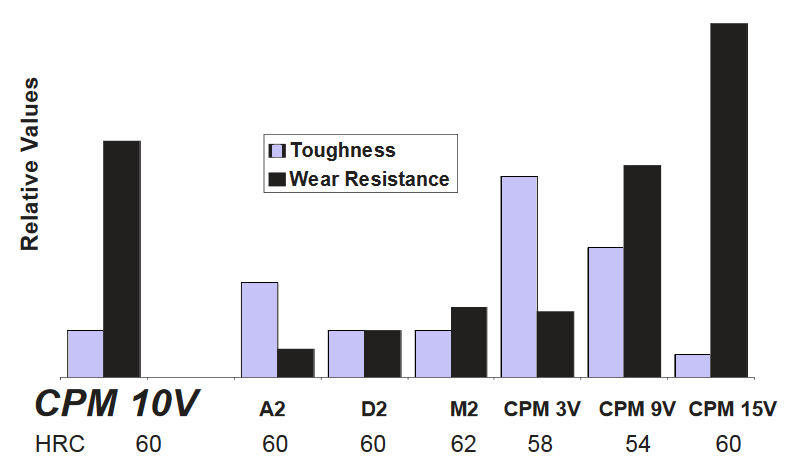

The V series differentiates based on the vanadium percent content. Figure 5 shows comparative performance. Note that the performance will change depending on the HRC hardness. However, for the specified hardness values both CPM 9V and CPM 10V are superior to D2 and M2. CPM 9V seems to have the best compromise of toughness and wear resistance.

|

|

|

In ultrasonic welding of copper to aluminum test strips using horns made of CPM 2V, 5V, 10Vand 15V, Smith[1] found that CPM 10V had the least wear and also produced the highest weld strengths (figure 6). (The original research for these graphs does not seem to be available.)

|

||||||||||

|

Vieira[1] has patented a tire cutting horn that is made from powdered metal with a vanadium content between 9% and 15% (claims 11 and 12). Using CPM 10V the patent predicts that this horn should last three times longer than a titanium horn (paragraph 0027). The patent seems to suggest that the wear is improved, in part, by the higher thermal conductivity of the steel, although this is not entirely clear (paragraph 0027). The patent says that the hardness should be in the range of HRC 50-64 but should not exceed 64 because the material becomes brittle and tends to chip (paragraphs 0025 and 0026). The patent says that steel horns draw "meaningfully higher power" compared to titanium (paragraph 0005). However, this is not addressed elsewhere so it is not known if the powdered metal reduces this problem.

CPM® 9V®

Characteristics — A tool steel with 9% vanadium. It is a modification of CPM® 10V® with lower carbon and vanadium to improve toughness, although its wear resistance is somewhat lower. Its machinability is twice as good as CPM® 10V®.

Heat treatment — HRC 54-56 (suggested for best combination of toughness and wear resistance). See data sheet.

Applications — Ultrasonic atomization of solder.

CPM® 10V®

Characteristics — A tool steel with 10% vanadium. It has high wear resistance and good toughness.

Heat treatment — HRC 60 (suggested for best combination of toughness and wear resistance — see data sheet). Dukane[2] (p. 59) recommends HRC 5256. However, Dukane notes, "Due to the hardness of the CPM10v horns, this causes them to be more brittle; thus, they are usually used for low amplitude applications. There are horn size limitations [unspecified] due to the brittleness." (Note — A brittle material does not have significant deformation beyond its yield point; chalk is an example. CPM 10V does not fit this definition and so is technically not brittle.)

"In the past, Dukane used D2 steel for this type of application. Working with metallurgists and through experimentation, we discovered CPM10V to be more reliable." (Dukane[2], p. 59) The criteria for reliability is not specified but may possibly be wear or fatigue resistance.

Applications — Ultrasonic tire cutting (Vieira[1] patent), metal insertion, welding glass filled parts, plunge cutting.

|

||||||

|

Rex® series

The Rex series has a high combination of vanadium, cobalt, and tungsten. These are high speed steels that are used in cutting tools.

Vieira[1] has patented a tire cutting horn that is made from powdered metal with combined vanadium, cobalt, and tungsten between 15% and 22% (claims 3 and 4). The patent suggests Rex 45, Rex 76, and Rex 86 (paragraph 0024). Maximum HRC hardnesses are mid-to-upper 60's. Note the relatively poor machinability of these materials (compare Table 5 to figure 7).

|

||||||||

|

Another suggested source is Hitachi Metals (their Hap series) (paragraph 0024).

Applications — Ultrasonic tire cutting (Vieira[1] patent).